Views: 10 Author: Site Editor Publish Time: 2023-05-09 Origin: Site

Making an insulating glass panel isn’t necessarily an easy process, and this is something that many people will have to get professional support with. However, if you have been looking to get insulating glass panels for your property, understanding the unique manufacturing process can offer many benefits. And so, with this thought in mind, we have outlined some of the key things you need to know about making these panels and the unique benefits – and challenges – that can come with this.

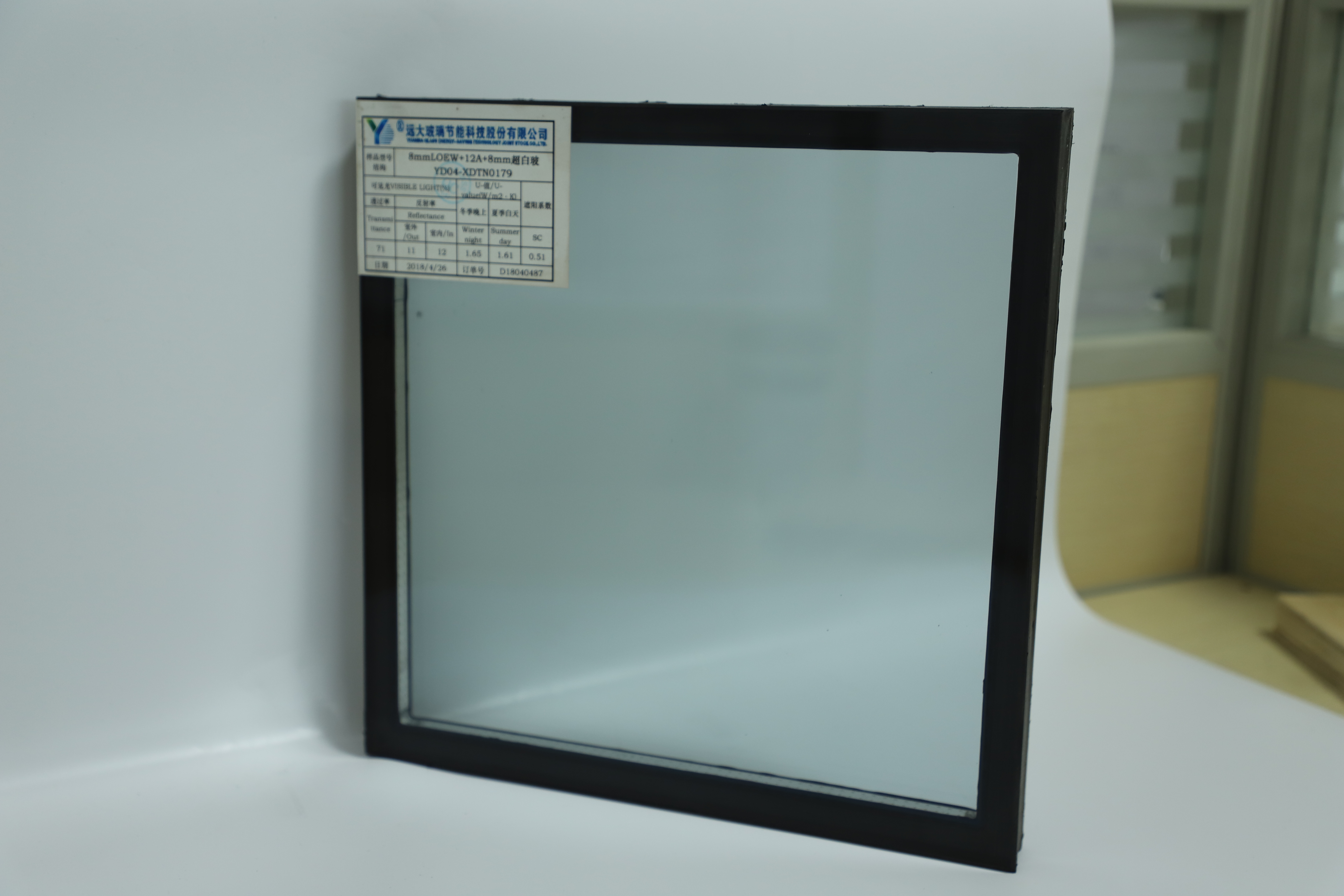

Before we look further, we should first consider briefly the key features of insulating glass panels. As the name would suggest, these particular designs are made to offer excellent insulating properties compared to regular glass panels, making them highly popular for a wide array of uses. Some of the key applications of insulating glass panels include homes, commercial properties, and equipment where energy efficiency is important.

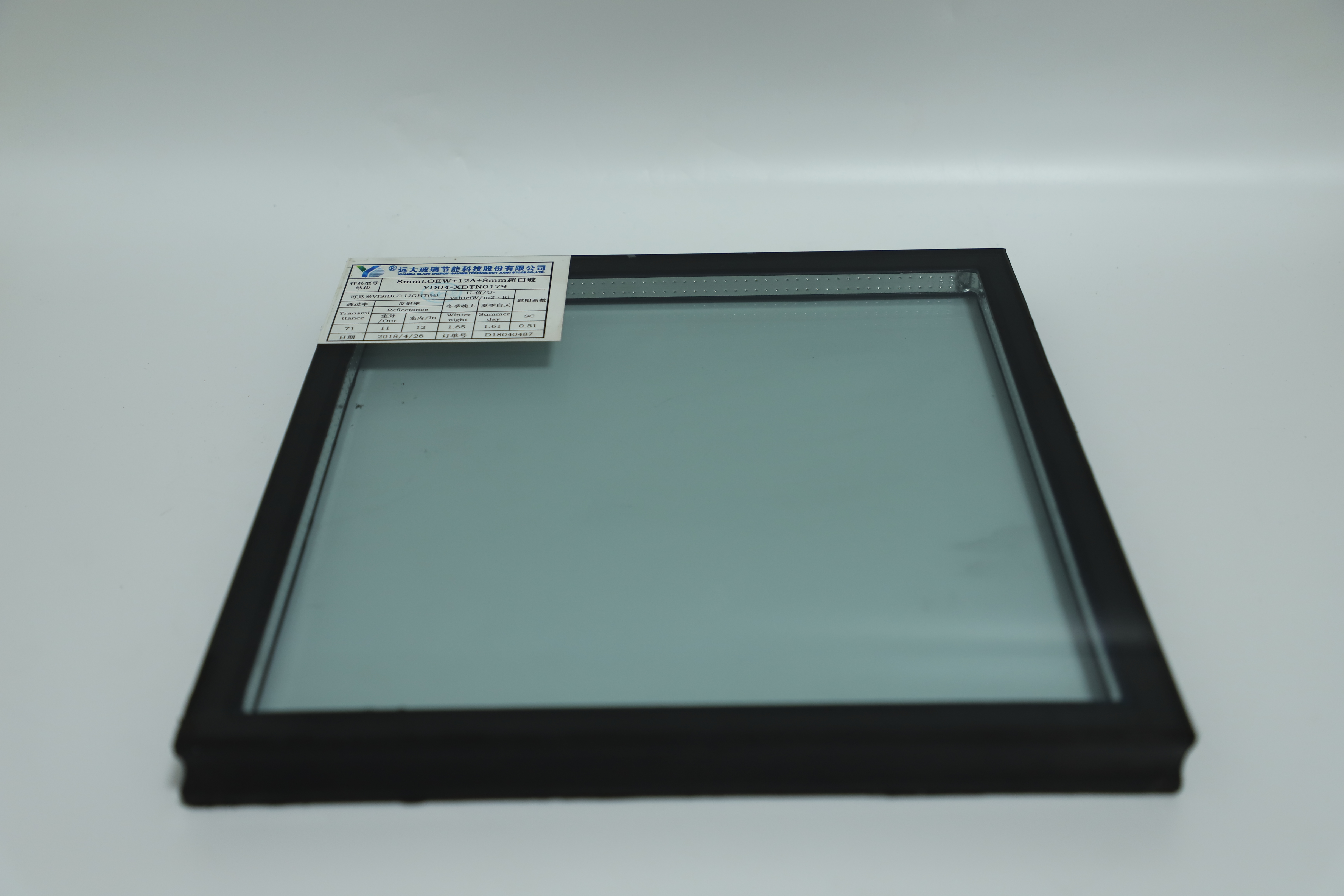

Insulating panels are made using a more complex process than regular glass panes since there’s a lot of work involved with actually sealing multiple panels together. Initially, once the glass has been created and prepared (often cut with a computer-controlled system), spacers then keep the panels apart, allowing for the perimeter to be sealed. From here, it is then possible for gas to be filled in the cavity using a valve or small hole, as required. Finally, the glass panes are then assembled, allowing for further work to be carried out on the system.

One of the most important aspects of creating an insulated glass panel is the quality control step since even small gaps in the sealant can allow moisture into the panel, which could then lead to condensation occurring with time. As such, when choosing an insulating panel, make sure to choose a team that focuses on the importance of quality to ensure the best results.

After the panel has been put together, it is also possible for further finishes to be applied as necessary, depending on the requirements of the client. For example, a growing number of modern customers opt to have Low-E coatings or laminates applied to their insulating glass panels before delivery, which helps further increase their practicality and appeal.

Of course, every manufacturer will have their own specific steps as part of this process. Keeping this in mind and opting for a manufacturer that is reputed for using a quality approach offers a simple way to streamline the process overall.

While many people assume that making an insulating glass panel is a straightforward process, the reality is a lot more complex than this. Indeed, insulating glass panels are a relatively tricky product to make due to their more complex designs and the considerations that need to be made to keep them working effectively. Nonetheless, with the right approach, insulating glass panels can be made to an incredibly high standard, and keeping this in mind can help you find the optimal designs for your own property or project. If you have further questions, please don't hesitate to contact us at chandler@yuanda-glass.com.